DC Worm Gear Motor Manufacturer

DC worm gear motor

NC Motor Co., ltd is leading manufacturer of DC motors. Our motors are widely used in the filed of Automatic door system, Health& Medical equipments, Automation machinery, Automobile and Aerospace industry.

We have nearly 20years history of designing& producing PMDC motor and BLDC motors. Our technology are fully developed in traditional brush gear reduction motor, Presently we are investing more into the production of brushless motors, which is high efficiency, low noise, stable reliability and long life time.

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About DC Worm Gear Motor

What Is a DC Worm Gear Motor?

Simply put, a DC gear motor is any electric motor coupled with a gear train. Gear motors use DC (Direct Current) power. In most cases, the gear reducer is intended to multiply the available output torque without increasing the power consumption of the motor while maintaining a compact size. The trade off for torque multiplication is a proportional reduction in the speed of the output shaft, and reduced overall efficiency. By utilizing the proper gear technology and ratio for specific applications, the optimal output and speed profiles can be obtained along with the perfect mechanical fit to unlock the maximum value of your OEM equipment.

This article provides you with everything you need to know about DC worm gear motor. What you’ll learn includes the uses of DC worm gear motors, its parts, the mechanism behind how it works and the different classifications of the DC worm gear motor. In the later end, you can check the difference between the brushless gear motor and the brushed gear motor.

What are DC worm gear motor Used For?

They can be found in the transmission systems of various kinds of machinery

- Automotive wiper and window motor

- Hospital beds and patient lifts

- Automatic door

- Automated production equipment

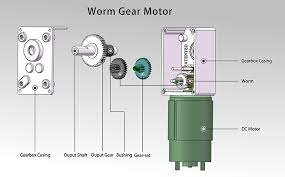

Worm gear motor parts

The first part of worm gear motors is the worm gear itself. This consists of a shaft with threading that spirals itself on the shaft. This worm gear is set into the splines of another gear. The rotational speed of the worm gear would in turn rotate the gear it is attached to. The second part of the motor, as the name suggests, is the motor. The motor is attached to the worm gear, turning it at different speeds depending upon the amount of torque produced by the main gear

How Does DC Worm Gear Motor Work?

Worm gear motors work by using a worm gear attached to a motor to move the main gear. This set up is ideal for a machine requiring a massive reduction ratio, meaning more torque for less speed. Secondly, the simplicity of the set up avoids the need for unnecessary gears in its operation.

Considerations When Buying DC Worm Gear Motor

In order to better buy the right product, you need to know the parameters of the product before you buy it. Here are the commonly used parameters

- Motor Type: Brushed or Brushless

- Voltage

- Output Speed

- Current

- Torque

- Shaft Material & Size

- Gear Material

- Shaft Configuration: (D Cut / Round / Splined / Other)

- Overall Size Parameters (L, W, H)

- Encoder Type: Optical / Hall Effect

- Additional Assembly Requirements (lead wires, connectors, etc.)

Brushed worm gear motor VS Brushless worm gear motor

DC brushed worm gear motor

DC brushless worm gear motor

In many applications, either a brushed or brushless DC motor can be used. They function based on the same principles of attraction and repulsion between coils and permanent magnets. Both have advantages and disadvantages that may cause you to choose one over the other, depending on your application’s requirements.

Brush DC motors have fast response, high starting torque, and rated torque performance from 0 to rated speed, but because brush DC motors produce constant torque performance under rated load, the armature magnetic field and rotor magnetic field need to use carbon brushes and commutators to maintain 90°. However, the carbon brushes and commutator generate frictional sparks during the operation of the miniature DC geared motor, resulting in shortened service life and increased noise.

Brushless motors are different from brushed motors in that they do not have brushes and commutators, which have a longer service life and lower noise, but the speed control is more complicated and more costly due to the structure.

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right DC worm gear motor you want.

- +86 13757884233

- info@motornc.com